Palletizers are useful in the small production lines because they avoid the heavy manual job and increase the overall safety of the workers. In the fast production lines palletizers are of course inevitable. We build automatic palletizers for both the small and the fast production lines. Our range starts with the cartesian palletizers and ends with the fast robot layer palletizers, passing trough the traditional single column or double column machines. For the canned products we also build magnetic head palletizers.

The Layer Palletizers

The layer palletizers prepare the product outside the machine’s gripping head. The packs enter the machine and are rotated, if necessary, by mechanical devices or by a couple of belts at different speeds and then stop in the correct position. The operation is repeated until the completion of the layer. In the case of layer palletisers with openable rollers, the layer is then transferred inside the head through mechanical arms. Once in the head the layer is compacted and then transferred to the platform.

Layer Palletizer MCPFP12

Low level infeed layer palletizer MCPFP12 is a very reliable palletizer for packs and bundles.It is equipped with a head with openable rollers that transfer the layer of product on the pallet. The product inlet can be on one or two lines. It can be equipped with pallet magazine or intersheet placing device.

Cartesian Palletizer

Cartesian palletizers are the best palletizing choice when the available space is limited. These type of palletizing robots are normally equipped with three brushless motors for the movement of the items in the three main directions (X, Y and Z). A fourth motor, when needed, is dedicated for the rotation of the head. Cartesian palletizing robots have the benefits of: small footprint, simplicity in mechanics, lower prices when compared to antropomorphic robots, highly accessible PLC driven motion control.

Cartesio 3

Our cartesian palletizer Cartesio3 is one of our bestselling machines and excels in reliability and flexibility. Cartesio 3 can be equipped with interlayer pad placing device, pallet conveyors and automatic pallet dispenser. The pattern collation is easily customizable by means of an intuitive interface in our hmi.

Magnetic Head Palletizers

Magnetic head palletizers use magnets to pick up ferrous materials, such as tin plated cans. They are usually used in the preserves sector and generally treat bulk product that is palletized directy on the pallet, without a secondary packaging. The loose product enter the machine and is arranged on

Magnetic Head MCPTM

Palletizer by magnetic head for tin cans. Automatic palletizer for tin cans placed in layers, onto wooden pallet, between which there are cardboard interlayers

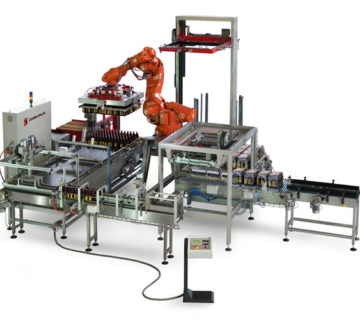

Palletizing Robot

Palletizing robot by full layer or by pliers. Robots can be used with success also for palletizing packs and bundles. Their speed and flexibility makes them a commonly used tool for palletizing products in many industries such as food, beverage pharmaceutical end petrochemical. The robot palletizers are generally divided in two main subcategories: the full layers palletizers that transfer a full layer of items to the pallet. The layer collation is created out of the pallet. The single or multi-item palletizers, that trasfer only parts of the layer on each cycle. The layer collation is created on the pallet. We have a great experience in robot palletizing and has helped several companies achieve the best palletizing solution for their specific need. The robot brands that we commonly use are: Kuka robots, ABB robots, Fanuc robots.

Robot

The robots used in these two categories mainly differ in their payload. The first is usually higher than 450 kg, the latter is normally around 180 kg.

The wrist of the robot is always facing downwards during the palletization phases and therefore robots with four degrees of freedom (or 4 axis robots) are used. The robots are always equipped with special grippers that are normally customized for the type of items to be transferred. The grippers can also include vacuum cups for interlayer handling and also hooks for empty pallet handling.

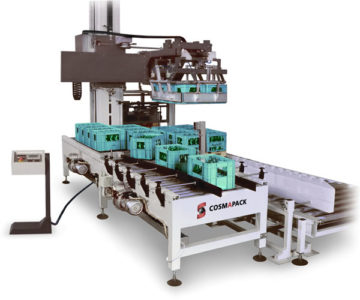

Automatic Palletizer for Crates

Sweep off palletizers allow a fast transfer of the product from the pallet to an accumlation table. The product is embraced by the sweeping off head, while the underlaying pad is blocked by pliers and the layer of product below the one to be transferred is blocked by means of a centering device. The top layer is at first transferred horizontally on a dead plate, then moved vertically at the height of the outfeed accumulation table on which it is transferred with a second horizontal movement. The product that has been transferred to the accumulation table is then aligned and put in a single lane conveyor

For crates

Machine designed to automatically palletize plastic crates arranged in layers on wooden or plastic pallets.

ARE YOU INTERESTED?

- +39 080 4968989

Our consultants are at your disposal to support and

drive you toward the best solution. Our success is

represented by fully satisfied customer

Realized by: V&G Technology – Concept: Cisternino Francesco

By using the site, you accept our use of cookies and the privacy policy More Information

This site uses cookies to provide the best browsing experience possible. By continuing to use this site without changing your cookie settings or by clicking on "Accept" you allow their use.